- Special Offers

- Transceiver Radio

- Transceiver Accessory

- Antennas

- Antenna Accessory

- Cable

- Connector

- Installation Material

- Installation Tools

- Measuring Equipement

- Body Worn Camera

- Electrosmog

- Telephone

- Baby Monitor

- Fever Thermometer

- Radio Device

- Set-top Boxes

- Personal Protective Equipment

- Motorcycle Helmet Speaker

- Car Equipment

- Voltage Converter

- Dry Cell

- Battery

- Battery Charger

- Emergency Signal

- Amber Signal

- Sound Signal

- Light and Sound Signal Accessory

- Traffic Engineering

- LED Lamp

- Smart Home

- Mosquito Repellent Device

- Market - Other Products

- Discontinued Products

YShield A300-HEMP Shading Fleece with Aluminum Coating

Key features of YShield A300-HEMP Shading Fleece with Aluminum Coating

• A300-HEMP is a stable fleece that is laminated on both sides with a thick micro-needled aluminum foil.

• Width: 90 cm

• Length: by the meter / 50 m roll

• Shielding attenuation: 123 dB

• sd value: 0.024 m = very high water vapor permeability

• Surface weight: 300 g/m² / Thickness: 0.4 mm

• Color: silver / silver

• Tear resistance: 4400 (transverse) - 6800 (longitudinal) N/m

• Corrosion resistance: corresponds to that of aluminum

• Materials: aluminium, cellulose (FSC, EUTR), polyester fibers (OEKO-TEX certified), adhesive powder (OEKO-TEX certified)

Further details of YShield A300-HEMP Shading Fleece with Aluminum Coating

A300-HEMP is a stable fleece that is laminated on both sides with a thick micro-needled aluminum foil. This provides redundancy and material thickness to meet the military standard MIL-STD-188-125.

This military standard for protection against very strong electromagnetic pulses (High Altitude Electromagnetic Pulse = HEMP) serves to protect critical infrastructure facilities. This standard does not only include minimum shielding of high-frequency fields, but also magnetic fields from 1 kHz. Produced in-house in Germany.

The micro-needling punctures the material 4000.000 times per square meter, making it highly permeable to water vapour. The micro-holes are so small that they have no effect on the sensational 123 dB shielding attenuation. The high water vapour permeability is a novelty, as two very thick aluminum foils are normally just glued on top of each other to reach MIL-STD-188-125.

Application

In order to meet the requirements of MIL-STD-188-125, two-layer processing is required; the test report from EMCC DR. RASEK refers to a two-layer installation. For professional contractors, our A300-HEMP is a solid basis for a complete shielding concept in accordance with MIL-STD-188-125, in which there are many details to consider: overlaps, doors, windows, cables, ventilation, etc.

For all shielding projects that do not require the low-frequency magnetic component, one-layer is completely sufficient, as redundancy is already provided with a single layer.

Processing

Substrate: absorbent and chalky substrates must be pre-treated with our GK5 primer. Bonding: no cellulose adhesive adheres to aluminum; we recommend our PSA pressure-sensitive adhesive, which creates a self-adhesive surface (very good adhesion with wet and dry installation). Overlap: the sheets must be glued with a 5 cm overlap. The edges of the sheets must also be sealed with our shielding tape HNX50 / HNX100. Contact materials: Due to the aluminum layer, a neutral pH value of pH 4-9 must be ensured for all direct contact materials during processing.

Grounding

This product with an electrically conductive surface has to be integrated into the functional-equipotential bonding (FEB).

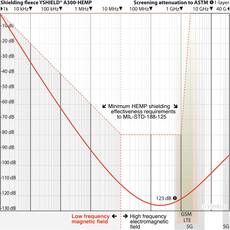

Shielding attenuation to MIL-STD-188-125

The conformity of this product with MIL-STD-188-125 has been tested by the accredited laboratory EMCC DR. RASEK accredited laboratory. This product meets the minimum shielding requirements for magnetic fields from 10 kHz to 10 MHz and high-frequency fields from 10 MHz to 1 GHz. In addition, the high-frequency fields from 1 GHz to 40 GHz were determined in accordance with ASTM D4935-10.

Laboratory & expert report of shielding attenuation up to 40 GHz

We have already invested in our own professional EMV laboratory years ago. We not only use it to create our laboratory screening reports but also to check each batch daily. Additionally, we have all our products checked by an independent, well-respected expert. Double checked maximum safety.